Published

Check weighing systems

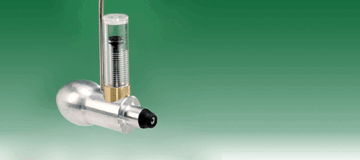

Kosan Crisplant’s check weighing systems are designed for accurate and quick control of the net content in LPG cylinders. The systems ensure correctly filled cylinders.

- Safe cylinders to your end-users

- Automatic sort-out of under- and overfilled cylinders

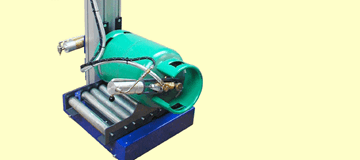

- Capacity up to 1,800 cylinders per hour

- Flexible for all cylinder diameters and heights

- Easy installation in existing plants

- Competitive price

Your benefits

Your benefits

- Check weighing of all filled LPG cylinders

- Automatic sort-out of under- and overfilled cylinders saves manpower and eliminates human errors

- High safety due to intrinsically safe network

- Easy and safe operation

- Easy calibration and zero-setting

- Minimum maintenance and service requirements

- Easy adjustment and maintenance

- Ready for integration in filling system network

- Ready for communication with PC for data collection

- Low installation costs

Your possibilities

Your possibilities

- Fully automatic, semi-automatic or manual operation

- Check weighing system in-line in chain conveyor with lifting table for stationary check weighing or with dynamic weighing table for continuous check weighing

- Check weighing system in-line in chain conveyor for fully automatic check weighing with automatic transfer of tare weight from central encoding station

- Check weighing system in-line in chain conveyor for semi-automatic check weighing with manual encoding of tare weight

- Check weighing system in-line in chain conveyor for semi-automatic check weighing with tare compare carried out by operator

- Stationary check scale for installation on floor

Your safety

Your safety

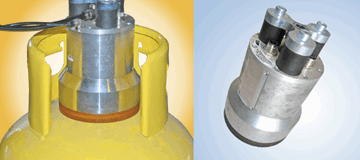

- Ex marking according to the ATEX Directive and applicable EN standards:

CE logo EX logo II 2G Ex h IIB T3 Gb

CE logo EX logo II 2G Ex h IIB T3 Gb - All check weighing systems are intended for operation in hazardous areas classified as Zone 1 or Zone 2 according to EN/IEC 60079-10-1

- All check weighing systems are designed and validated in accordance with a certified ISO:9001 quality management system; furthermore, they are designed according to all relevant requirements set out in applicable EU Directives

- All check scales have weighing Accuracy Classification C3 according to OIML R 76/EN45501