Published

Weight correction machines

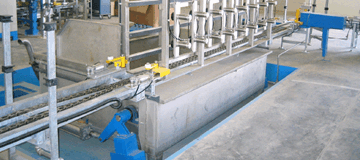

Kosan Crisplant’s weight correction machines are designed to perform safe and accurate weight correction of the LPG content in incorrectly filled cylinders. Weight correction is obtained by filling or evacuating the LPG cylinder.

- Weight correction on the spot

- Flexible for all valves types

- Flexible for all cylinder diameters and heights

- Automatic check weighing after weight correction

- Easy installation in existing plants

- Minimum space requirements

- Independent units

- Ready for communication with PC for data collection

Your benefits

Your benefits

- Fast and correct weight correction

- No accumulation of incorrectly filled cylinders

- Minimum time spent on incorrectly filled cylinders

- High safety due to intrinsically safe network

- Easy and safe to operate

- Low power consumption

- Minimum maintenance

Your possibilities

Your possibilities

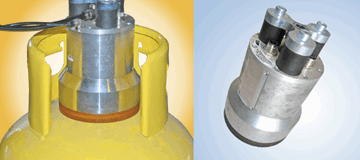

- Tiltable evacuation rack for domestic cylinders

- Stand-alone tiltable evacuation rack for industrial cylinders

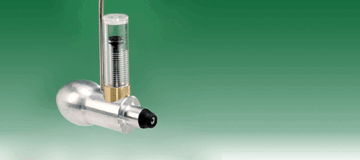

- Manual or automatic head for filling and evacuation

- One machine can be equipped with various heads for filling and evacuation

- Stand-alone machine or incorporated in roller conveyor

Your safety

Your safety

- Ex marking according to the ATEX Directive and applicable EN standards:

II 2G Ex h IIB T3 Gb

II 2G Ex h IIB T3 Gb - All weight correction machines are intended for operation in hazardous areas classified as Zone 1 or Zone 2 according to EN/IEC 60079-10-1

- All weight correction machines are designed and validated in accordance with a certified ISO:9001 quality management system; furthermore, they are designed according to all relevant requirements set out in applicable EU Directives

- All weight correction machines have weighing Accuracy Classification C3 according to OIML R 76/EN45501