Published

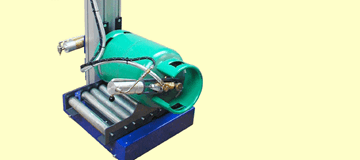

Electronic leak detectors and valve testers

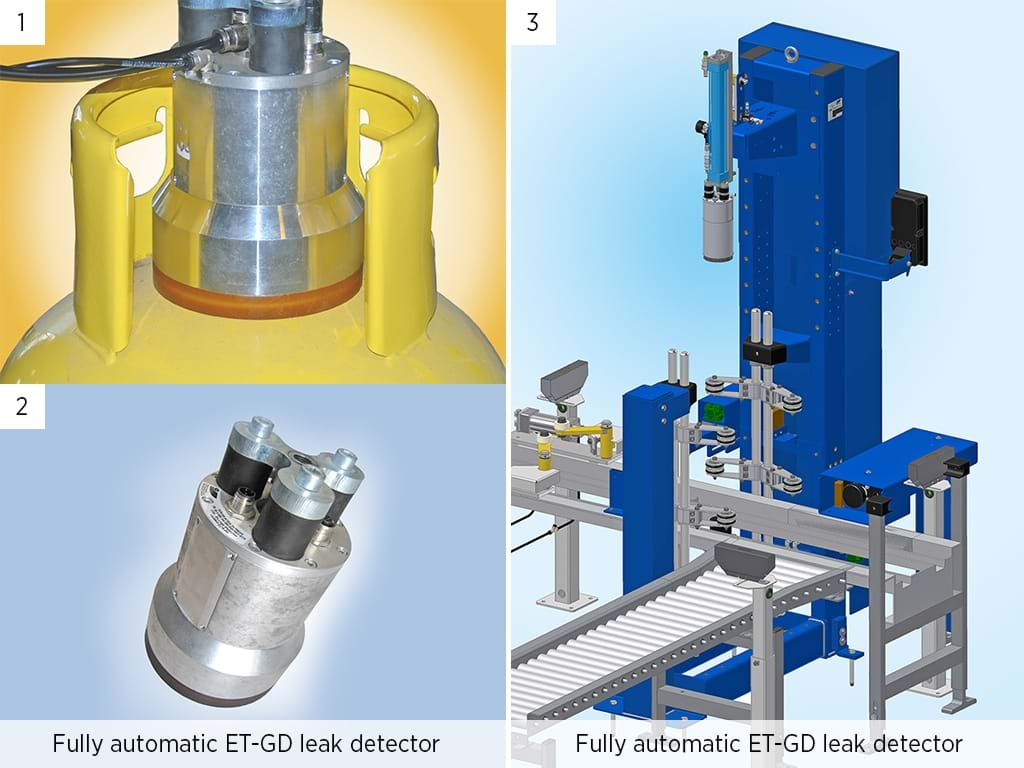

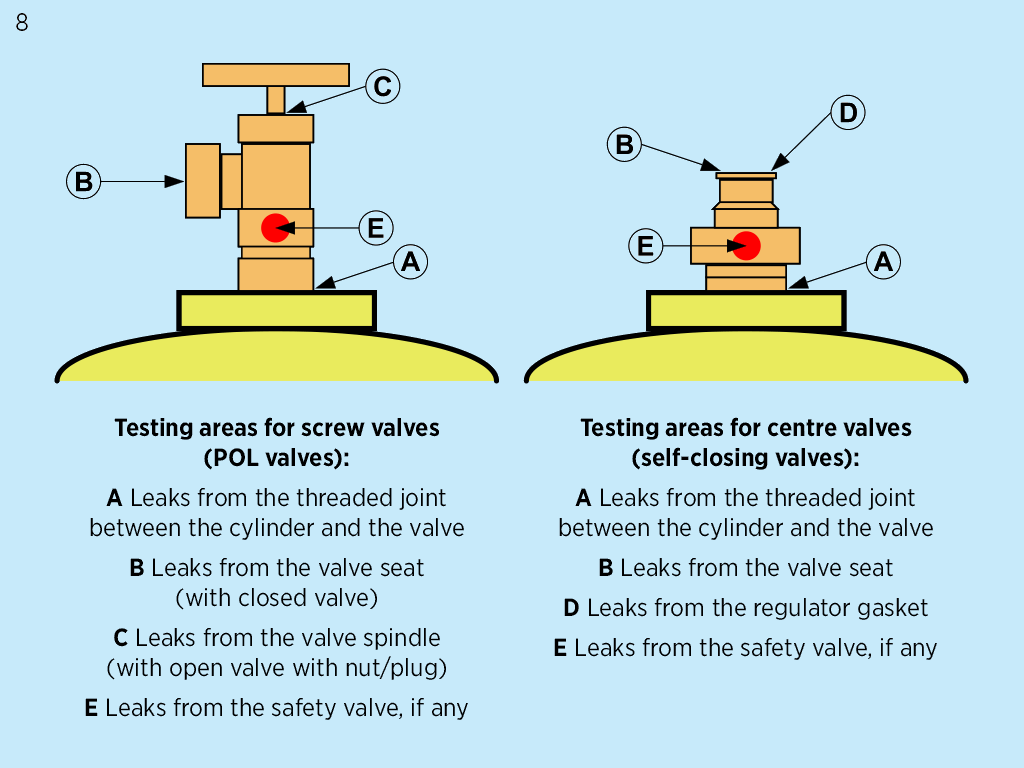

Kosan Crisplant’s electronic leak detectors and valve testers perform tests on LPG cylinder valves. The cylinders are approved or rejected according to preset permitted values.

- Provide maximum safety

- Fully automatic test with same sorting limit

- Eliminate human errors

- Detect all kinds of leak around the valve

- Check the valve form (centre valves only)

- Flexible for all types of valves

- Flexible for all cylinder diameters and heights

- Easy installation in existing plants

- Minimum space requirements

- Competitive price

Your benefits

Your benefits

- Safe cylinders to your end-users

- 100% test – all filled cylinders are tested

- Savings on manpower thanks to automatic sorting of cylinders with unapproved valves

- Easy to use calibration tools and procedure

- Easy adjustment and maintenance

- Low power consumption

- Air service unit with extra filters to eliminate pollution in pneumatic air supply

- Minimum maintenance

- Easy to set up: all necessary software is installed in the HMI/CUC controller

- Easy to use: clear text display and sturdy keyboard

- Ready for integration in fully automatic filling system

- Ready for communication with PC for data collection

Your possibilities

Your possibilities

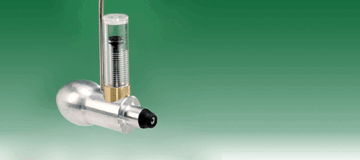

- Test heads designed for all types of valves

- Testing principle according to valve type and testing area on valve: gas analysis principle (leak detectors) or pressure rise/drop principle (valve testers)

- Manually operated model for installation (1) stationary on floor, (2) by a chain conveyor or (3) by a roller conveyor. Available with gas analysis principle. Manually height adjustable.

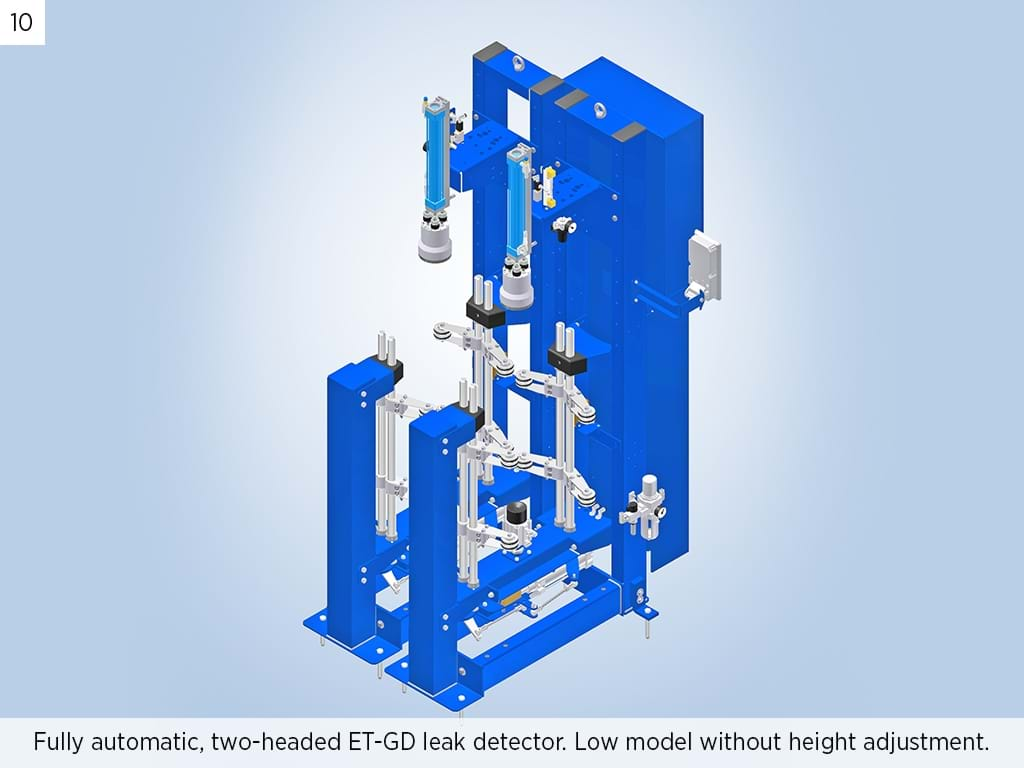

- Fully automatic model for installation in-line in chain conveyor. Performs test on all cylinders. Available with gas analysis principle or pressure rice/drop principle. Manual change of test head for test of different valves. One- or two-headed machine. For one fixed cylinder height. Manually or automatically height adjustable

- Calibration and test equipment available on demand

Your safety

Your safety

- Ex marking according to the ATEX Directive and applicable EN standards:

CE logo EX logo II 2G Ex h IIB T3 Gb

CE logo EX logo II 2G Ex h IIB T3 Gb - All electronic leak detectors and valve testers are intended for operation in hazardous areas classified as Zone 1 or Zone 2 according to EN/IEC 60079-10-1

- All electronic leak detectors and valve testers are designed and validated in accordance with a certified ISO:9001 quality management system; furthermore, they are designed according to all relevant requirements set out in applicable EU Directives