Published

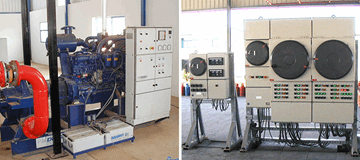

Production data and management system

Kosan Crisplant’s Production Data Management System collects data from filling process machines controlled by the HMI/CUC controller. The data is monitored and serves as a basis for reports concerning the filling process.

- Automatic collection of all important production data

- High safety level due to production surveillance

- Effective tools for viewing and analysing production data

- PC monitoring of real time production status

- Report statistics for filling hall production overview

- Easy identification of maintenance and adjustments needs

- Ready for direct connection to existing CUC network

Your benefits

Your benefits

- Analysis of both single machine capacity and filling plant capacity

- Overview of production interruptions and of development in filling capacity

- Analysis of single machine filling accuracy and adjustment need

- Survey of total production filling accuracy

- Review of cylinders rejected at check scales and leak detectors

- Reports per cylinder type and for given time periods

- On-line supervision of all HMI/CUC controllers including alarm log and status overview

- Elaboration of presentation graphs on the basis of report data

- Efficient data storage and search in database

- Disaster recovery incl. quick re-installation of PC in case of crashing

Your possibilities

Your possibilities

- Installation of PC in non-hazardous area up to 500 meters from filling hall

- One PC can collect and handle data from up to 10 carrousel filling systems simultaneously

- Update of software via modem

- Standard high-quality PC with DVD-RW drive, keyboard, mouse, flat screen, and colour printer

- Standard software (e.g. Microsoft Windows, SQL database, etc.)

- Kosan Crisplant software (CUC Monitor, RCC Reports)

Your safety

Your safety

- Hardware and software according to international standards