Published

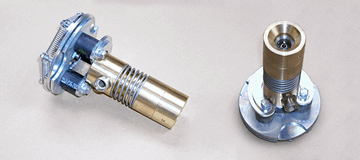

KCFiLL1 filling unit

Kosan Crisplant’s patented KCFiLL1 filling machine is designed for easy, safe and accurate filling of all types of LPG cylinders and valves, and offers the best value for money on the market for low-capacity filling machines.

- Weighing principle with load cell

- Easy and safe manual operation

- Unlimited installation possibilities

- Flexible to different cylinder diameters, heights and cylinder valves

- Simple design with thoroughly tested components

- Competitive price: best value for money on the market

Your benefits

Your benefits

- Easy and quick installation

- Satisfied end-users due to accurately filled cylinders

- Savings on LPG because of high filling accuracy and intelligent filling software

- Plug'n'play solution: minimum installation costs

- Minimum maintenance and service requirements

- Low power consumption

- Easy and safe to operate

- Minimum manual handling of heavy cylinders when using a semi-mobile KCFiLL1 solution

- High safety due to intrinsically safe system

- Easy adjustment and maintenance (error messages in display)

- Can be integrated in existing filling system network

- No need for separate check weighing equipment: filling and check weighing processes performed by the same unit

Your possibilities

Your possibilities

- Unlimited installation possibilities:

– Fixed installation (e.g. on a suspension frame with a minimum load-carrying capacity of 500 kg per installed unit)

– Semi-mobile installation (e.g. on a swing crane or on a frame with wheels)

– Mobile installation (e.g. in a container, as a skid-mounted installation or on a truck – either fixed or on a swing crane) - The cylinder flow to and from fixed KCFiLL1 units is carried out manually or by using chain or roller conveyors

- Configuration possibilities:

– Manual or automatic connection of filling head

– With or without lifting device for filling head

– Including external lifting table or weighing plate - Data collection pack, including complete PC system or connection to existing Kosan Crisplant PC system, is available as an option

- Developed specifically for low capacity random or batch filling and/or for filling of cylinders in different sizes with different valves

Your safety

Your safety

- Ex marking according to the ATEX Directive and applicable EN/IEC standards:

II 2G Ex "ib" IIB T4 Gb

II 2G Ex "ib" IIB T4 Gb - The KCFiLL1 unit is manufactured under the supervision of the Bureau Veritas certification approved quality management system which conforms with EN/IEC 80079-79:2011 (Bureau Veritas certification number: LCIE 13 ATEX Q 4003)

- The KCFiLL1 unit is IECEx type approved and in compliance with the European ATEX Directive

- The KCFiLL1 unit is intended for operation in hazardous areas classified as Zone 1 or Zone 2 according to EN/IEC 60079-10-1