Published

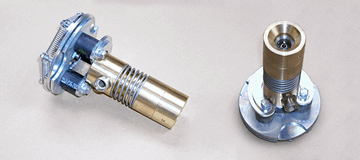

UFM – universal filling machine

Kosan Crisplant’s UFM universal filling machine is designed for safe and accurate filling of all types of LPG cylinders and valves.

- Most used filling machine in the world

- Weighing principle (load cell) or mass flow principle

- Operation; fully automatic, semi-automatic or manual

- Installation: on carrousel, in-line in roller or chain conveyor, or as stand-alone unit

- Flexible to different cylinder diameters, heights and cylinder valves

- Modular design with thoroughly tested components

- Competitive price

Your benefits

Your benefits

- Satisfied end-users due to accurately filled cylinders

- Savings on LPG because of high filling accuracy and intelligent filling software

- Low installation costs due to intrinsically safe system

- Minimum maintenance and service requirements

- Low power consumption

- Easy and safe to operate

- High safety due to intrinsically safe system

- Easy adjustment and maintenance (error messages in display)

- Ready for integration in filling system network

- Ready for communication with PC for data collection

Your possibilities

Your possibilities

- Carrousel models for high capacity batch filling (from approx. 300 cylinders per hour) and/or for automated filling. Operation can be manual, semi-automatic or fully automatic

- In-line in chain conveyor models for low capacity filling (up to approx. 300 cylinders per hour) or/and for automated handling of cylinders (especially big and/or heavy cylinders)

- In-line in roller conveyor for low capacity filling

- The modular design allows for rebuilding of existing filling machines

- Stationary on floor models for low capacity random or batch filling and/or for filling of cylinders in different sizes /with different valves

Your safety

Your safety

- Ex marking according to the ATEX Di-rective and applicable EN standards:

II 2G Ex h IIB T3 Gb

II 2G Ex h IIB T3 Gb - All filling machines are intended for operation in hazardous areas classified as Zone 1 or Zone 2 according to EN/IEC 60079-10-1

- All filling machines are designed and validated in accordance with a certified ISO:9001 quality management system; furthermore, they are designed according to all relevant requirements set out in applicable EU Directives

- All filling machines have weighing Accuracy Classification C3 according to OIML R 76/EN45501