LNG bunkering pontoon enables simultaneous operation

Customer

ENGIE, France

Fluxys, Belgium

The customer's challenge

ENGIE and Fluxys wanted to move their LNG bunkering from land to the water.

Our solution

We pre-engineered a bunkering pontoon with the optimal cryogenic outfitting, allowing for easy and efficient bunkering.

The outcome

If built, the designed pontoon will carry 1-4 tanks and grant its owners a flexible way to bunker their ships while reducing traffic and congestion at the dock.

Bunkering from a land-based installation is not the right solution for every situation – no matter if the solution is movable or permanent.

French energy giant ENGIE and Belgian transmission system operator Fluxys had also come to this conclusion when they chose KC LNG and the Dutch ship designer Conoship to come up with a concept for an LNG bunker pontoon.

Finding the perfect solution

The project was a pre-engineering study to develop the optimal design, with Conoship designing the pontoon itself while KC LNG was charged with the cryogenic outfitting. This included the integration of the tanks and pipes, location of flanges as well as calculating how the bunkering would work and planning the handling of hoses – in short, everything related to the actual bunkering process.

More free space at the dock

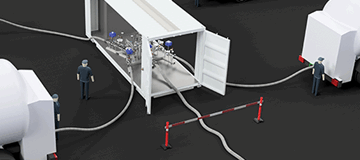

This pontoon, which is designed to carry between 1 and 4 LNG tanks, has several advantages. By not having trucks going to and from the ship when it needs bunkering, it reduced the traffic that is a challenge at many harbours. Furthermore, it allows for simultaneous operations ("sim ops") – the simultaneous process of loading and offloading cargo or passengers on the dock side of the ship while filling its fuel tanks from the other side.

Since the pontoon has no engine of its own, it must be guided to its destination by a tugboat. Alternatively, a ship can moor next to the pontoon while it sits at the dock.