Published

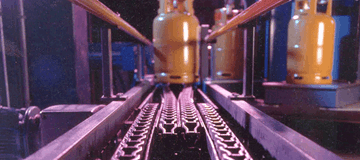

Palletizing systems

Kosan Crisplant’s palletizing systems are designed for safe and efficient handling of all kinds of pallets as well as for automatic loading and unloading of LPG cylinders.

- High safety and optimal logistics at the filling plant

- Minimum time consumption for loading and unloading of trucks

- Fully automatic plant

- Minimum need of manpower

- High capacity – up to 2,400 cylinders per hour

- Careful transportation of cylinders between filling plant, storage and customer

- Flexible design for handling of many pallet types

Your benefits

Your benefits

- High safety as only internal vehicles operate near by the filling plant, and only few external people has access to the plant

- Optimal logistics as, to a large ex-tent, external and internal vehicles operate in separate areas

- Possibility of expansion thanks to flexible and modular design

- Just few cylinder repairs necessary as cylinders are protected in pallets during transport

- Just few industrial injuries as there are no manual cylinder lifts

Your possibilities

Your possibilities

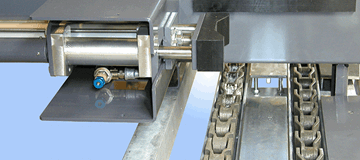

- Two basic palletizers: Compact Pal-letizer and Linear Palletizer

- Both plant types can be connected to all types of chain conveyors

- Both plant types can be supplied with fully automatic bar lifter

- The Compact Palletizer is available in one or two storeys and with a ca-pacity of up to 2,400 cylinders per hour

- The Linear Palletizer is available in one storey and with a capacity of up to 1,800 cylinders per hour

- The Linear Palletizer has modular design so that the internal buffer storage can be varied

- The Linear Palletizer can be supplied with a pallet stacker/destacker in order to minimize the fork-lift truck operations and/or to reduce the number of fork-lift trucks

- Manual or semi-automatic palletiz-ers for low capacity filling plants

Your safety

Your safety

- Ex marking according to the ATEX Directive and applicable EN stand-ards:

CE logo EX logo II 2G Ex h IIB T3 Gb

CE logo EX logo II 2G Ex h IIB T3 Gb - All palletizing systems are intended for operation in hazardous areas classified as Zone 1 or Zone 2 ac-cording to EN/IEC 60079-10-1

- All palletizing systems are designed and validated in accordance with a certified ISO:9001 quality manage-ment system; furthermore, they are designed according to all relevant requirements set out in applicable EU Directives