Published

Conveyor systems

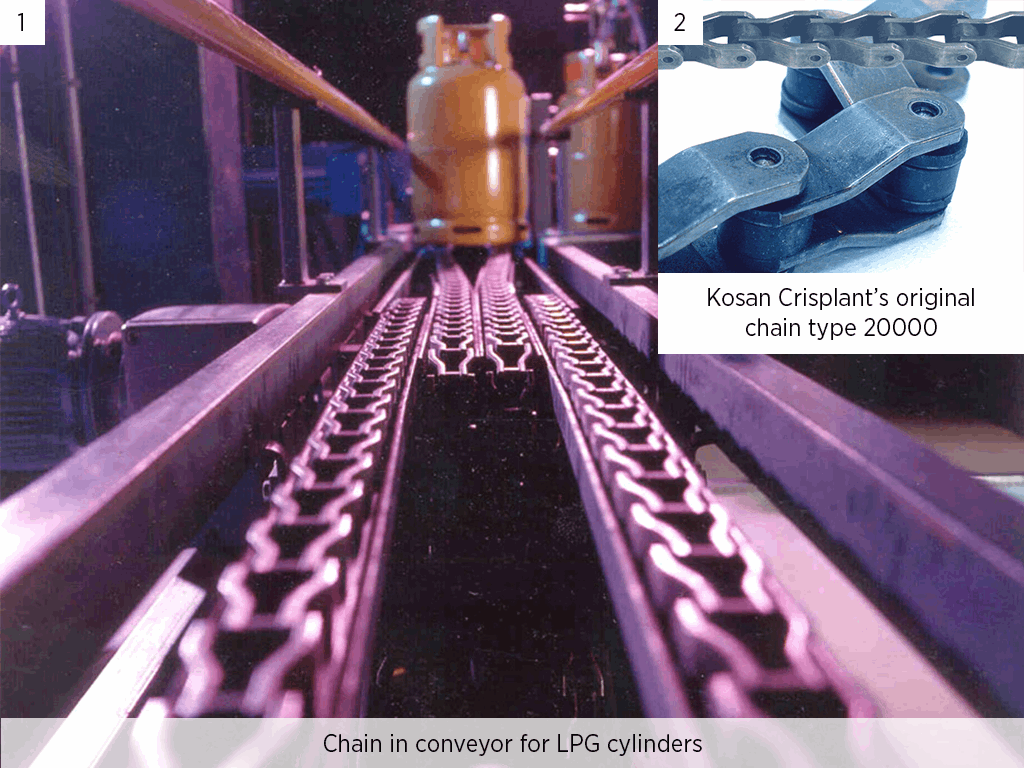

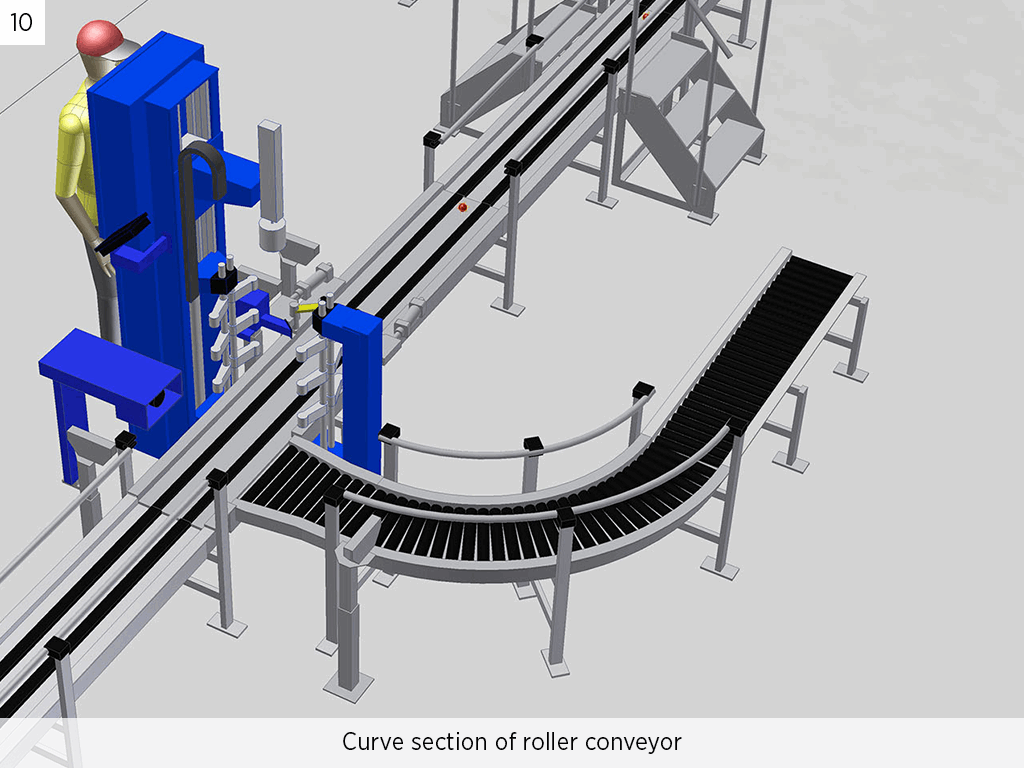

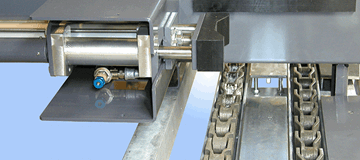

The conveyor systems are designed for efficient and rational transport of LPG cylinders from the unloading point to the loading point, passing various processing points.

- High quality and solid systems developed on the basis of 50 years’ experience

- Rational transport of LPG cylinders

- Modular and flexible systems

- Layout according to requirements

- Systems for all cylinder types

- Manual or fully automatic control of cylinder flow

- Integration with machines and processes

- Fully galvanized

Your benefits

Your benefits

- Minimized strain on operators

- Capacity increase thanks to optimi-sation of manual processes

- Minimum need for manpower

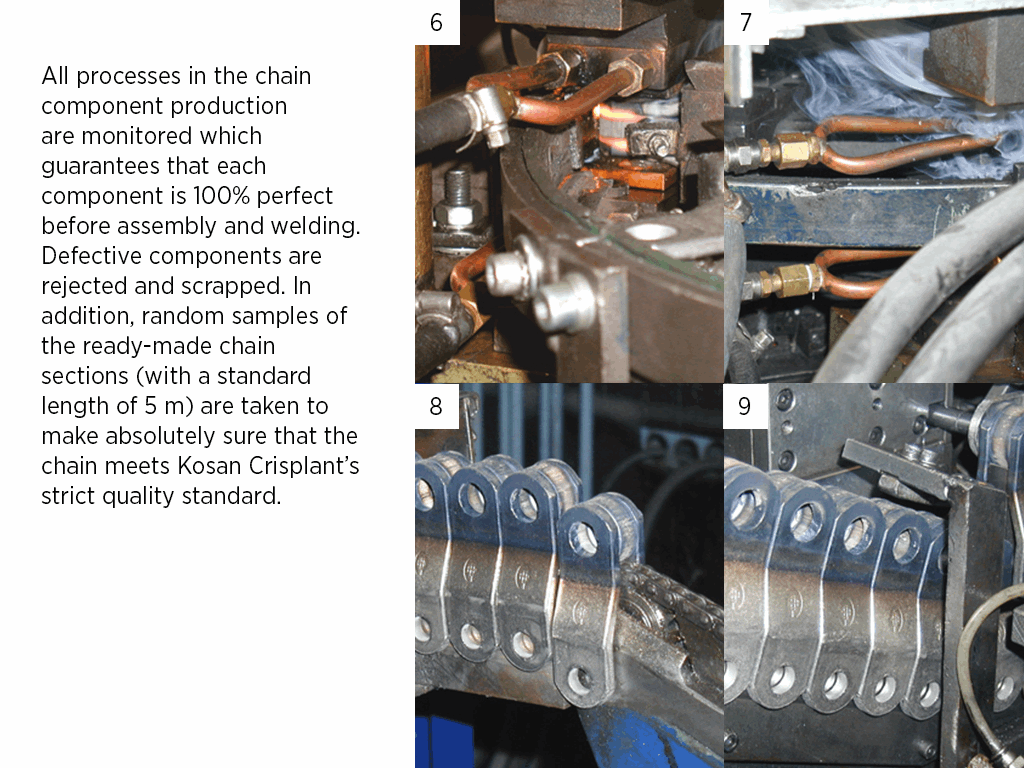

- Lasting quality

- High safety thanks to controlled cyl-inder logistics

- Reduction of typical handling dam-ages on cylinders

- Minimum wear, low power con-sumption and noise level when us-ing soap water lubricated chain conveyor

Your possibilities

Your possibilities

- Dry or soap water lubricated chain conveyor

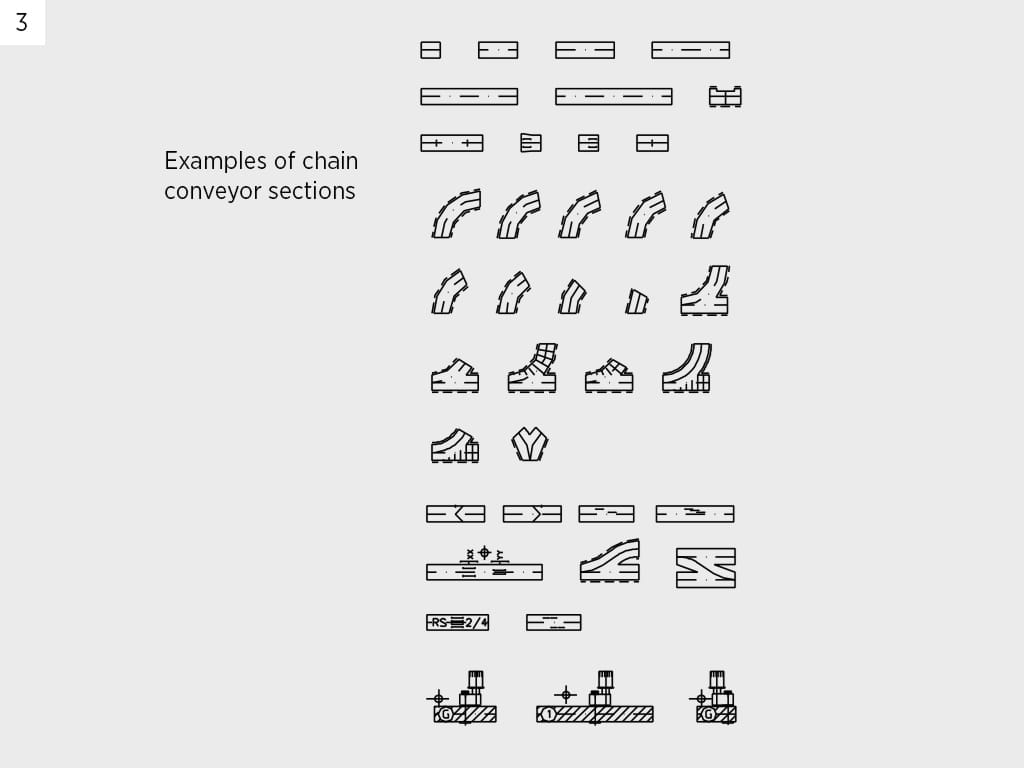

- Ascending and descending chain conveyors

- The modular principle allows infinite combinations

- Driving units with ex-proof motor and gear for variation in chain conveyor speed

- Chain conveyor systems with two or three chains and different widths

- Convergence and divergence units for chain conveyors

- Reversion sections for variation in chain conveyor speed

- Installation at floor level or on supports at a given level

- Pusher for discharge conveyor

- Manual, semiautomatic or fully automatic control of cylinder flow

- Central system for distribution of soapy water

Your safety

Your safety

- Ex marking according to the ATEX Directive and applicable EN standards:

CE logo EX logo II 2G Ex h IIB T3 Gb

CE logo EX logo II 2G Ex h IIB T3 Gb - All conveyor systems are intended for operation in hazardous areas classified as Zone 1 or Zone 2 ac-cording to EN/IEC 60079-10-1

- All conveyor systems are designed and validated in accordance with a certified ISO:9001 quality management system; furthermore, they are designed according to all relevant requirements set out in applicable EU Directives